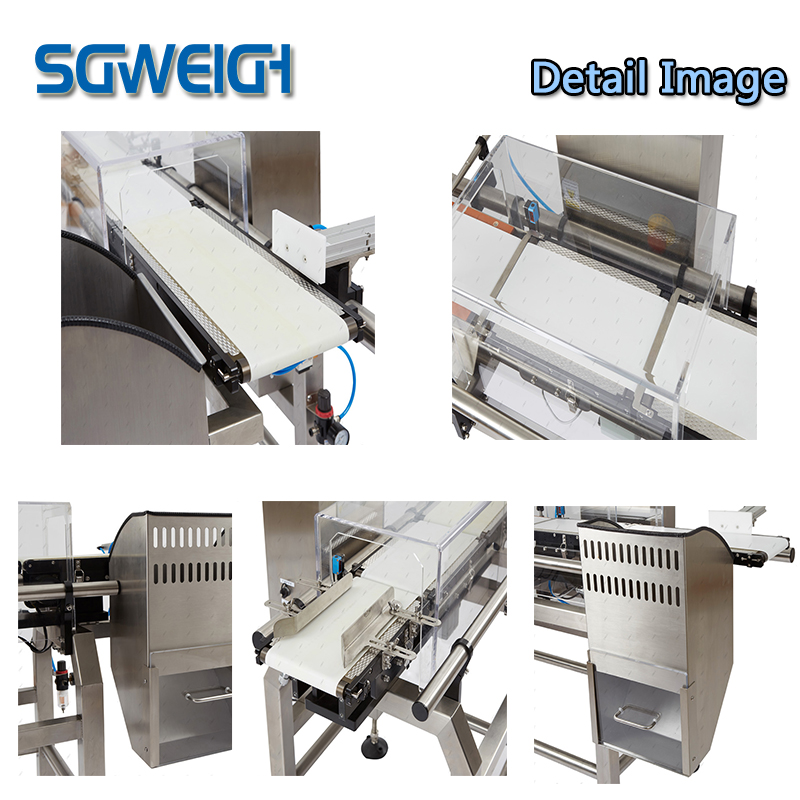

Product Details

Product Summarize

The Integrated Metal Detector Checkweigher adopts high-speed digital signal processing devices and intelligent algorithms, which can detect metals in frozen foods (such as dumplings, frozen fish), meat, rice, pickled products and other foods.High-speed digital signal processing devices and intelligent algorithms are used to improve detection accuracy and stability. The Metal Detector With Check Weigher Machine is composed of a metal detection part, a weighing part and a conveying and rejecting device. The detection and weighing are integrated, which is convenient to operate and saves time. It has very powerful functions.Welcome to consult for quotation information!

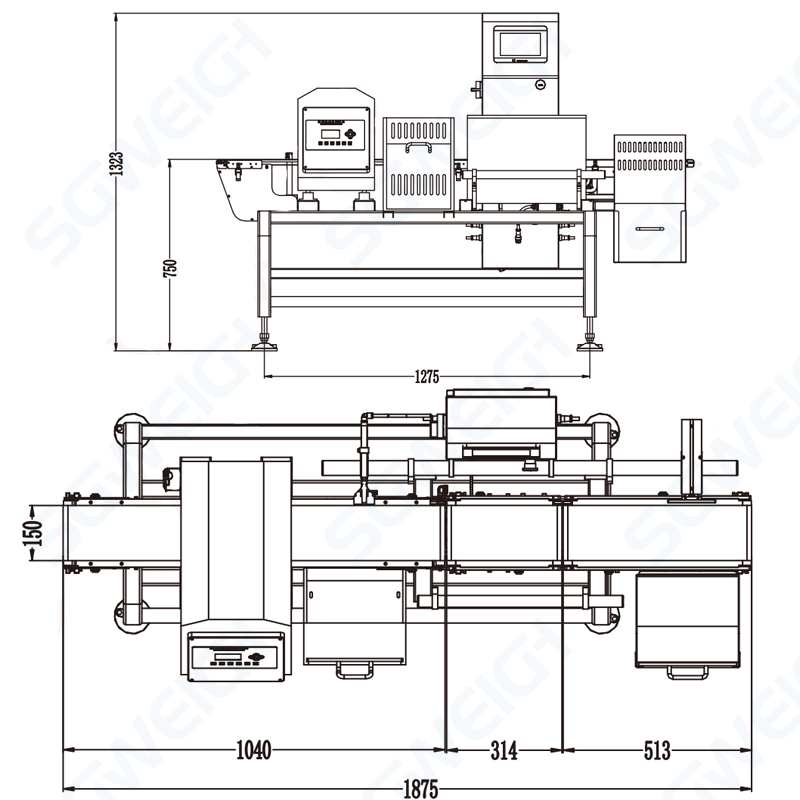

Product Parameter

Detection method: electromagnetic induction / digital load cell

Size: 330×150mm

Accuracy: FE0.8mm SUS2.0mm

Sorting accuracy: ±0.5 grams

Weighing range: 5g-900g

Through height: 110mm

Through width: 280mm

Packing length: ≤300mm

Display division value: 0.1g 0.2g 0.5g 1g

Sorting segment number: 3 segments

Sorting capacity: 60 times/min

Conveyor belt speed: 10-45 m/min

Height from the ground: 735mm—800mm

Working temperature: 0-40℃

Weight: about 160 kg

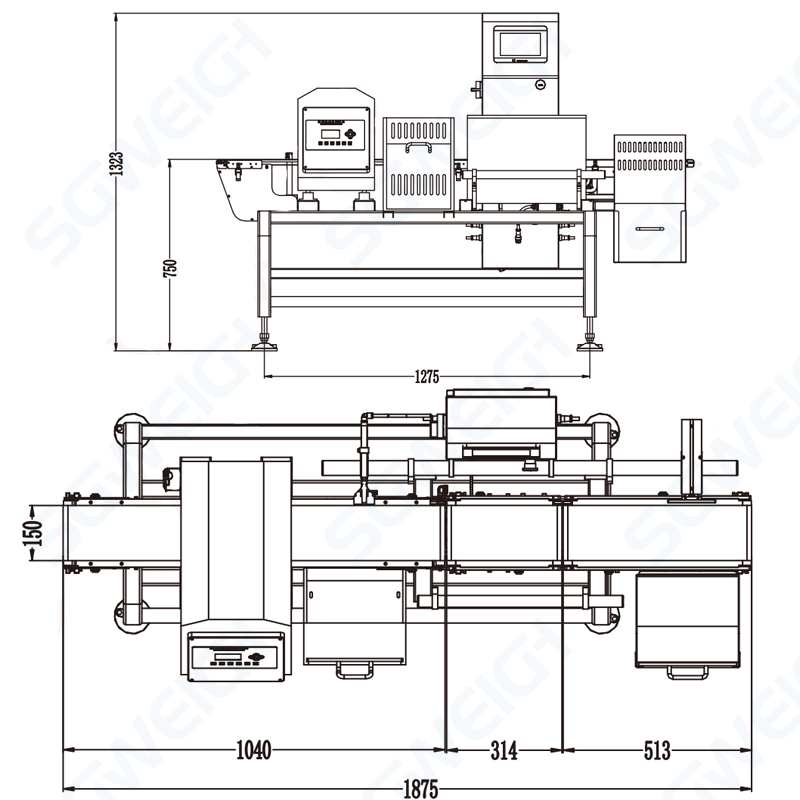

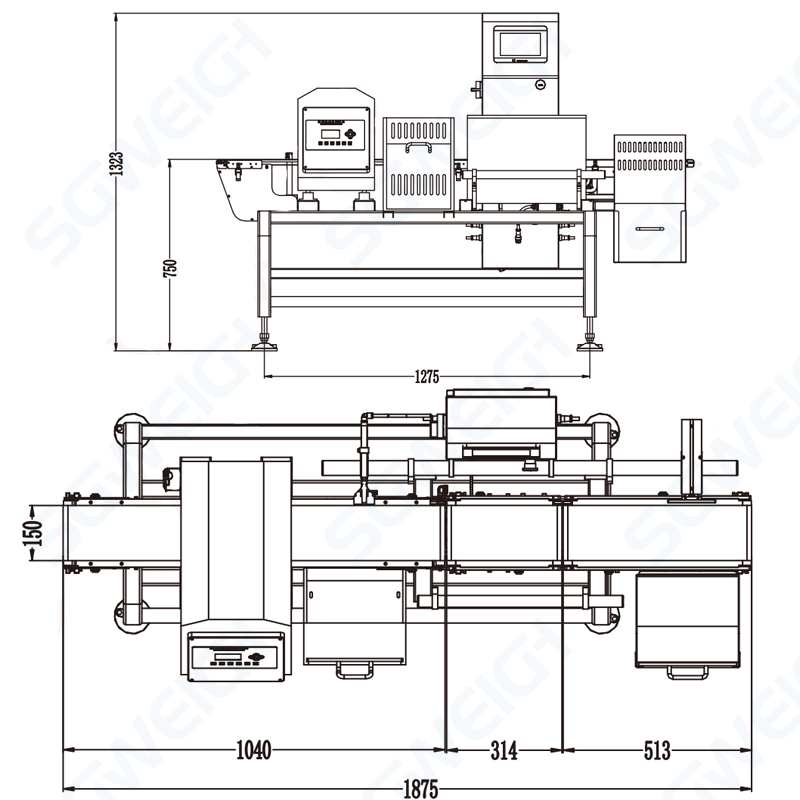

Dimensions: 1900mm×700mm×1120mm (L×W×H)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Product Characteristics

1. Reverse detection

It adopts high-precision imported through-beam switch and cooperates with the curve fitting algorithm to accurately complete the reverse detection.

2. Customization ability

can be equipped with scanning guns to meet various special requirements of deep customization and function development

3. Easy and intelligent operation

with wide LCD and wizard interface, users can easily set up and operate.

4. Reliable data

use FRAM storage technology to ensure system parameters and data.

5. Advanced manufacturing technology

the metal detector adopts all stainless steel probes and frames, and various protection levels are available for customers to choose, adapting to various production environments.

6. Conveyor belt anti-deviation design

The metal detector adopts a special conveyor belt anti-deviation design scheme to effectively avoid the deviation of the conveyor belt.

7. Abundant peripheral interfaces

RS-485 data communication, PLC programming nodes, and printer output can be configured, which can provide real-time data for the production management system for remote control, analysis and monitoring,

and provide valuable traceability information.

8. Rejecting device

Equipped with blocking arm type, blowing type, flap type, push rod type and other rejecting devices.

Specific Application

Customer Visit

Exhibition

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.

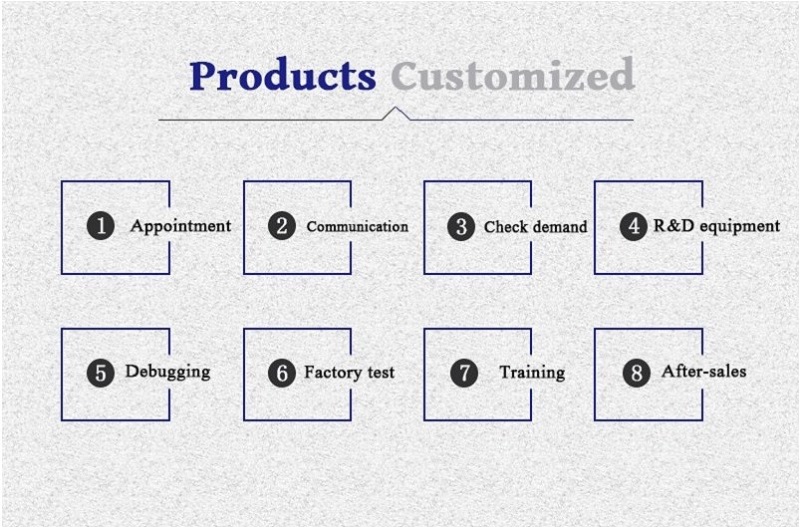

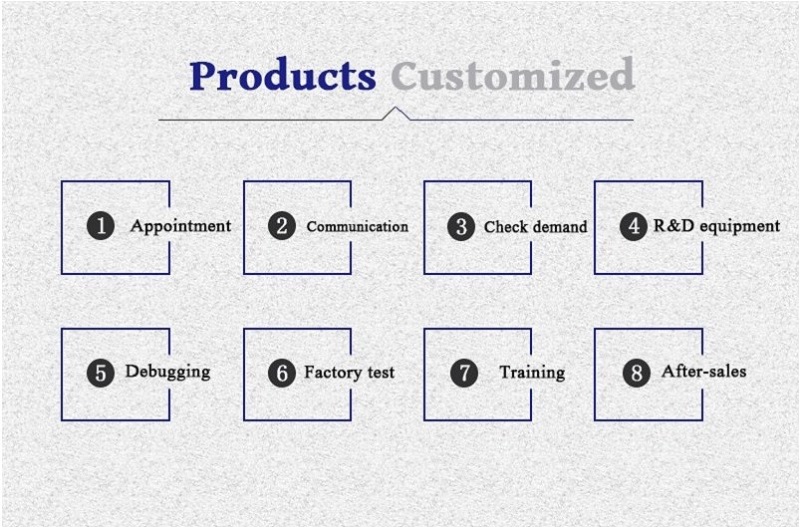

Customized Process

1st step:Customer has showed his special requirements.

2nd step:We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step:Making the conceptive CAD drawing based on communication and understanding.

4th step:Making the detail and 3D drawing agter fixed the design and other details.

5th step:Offer the quotation after confirm the design,material and surface treament.

6th step:Making the sample for approval.

7th step:Testing installation after demo mock up.

8th step:Big production delivery and service after sales.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo