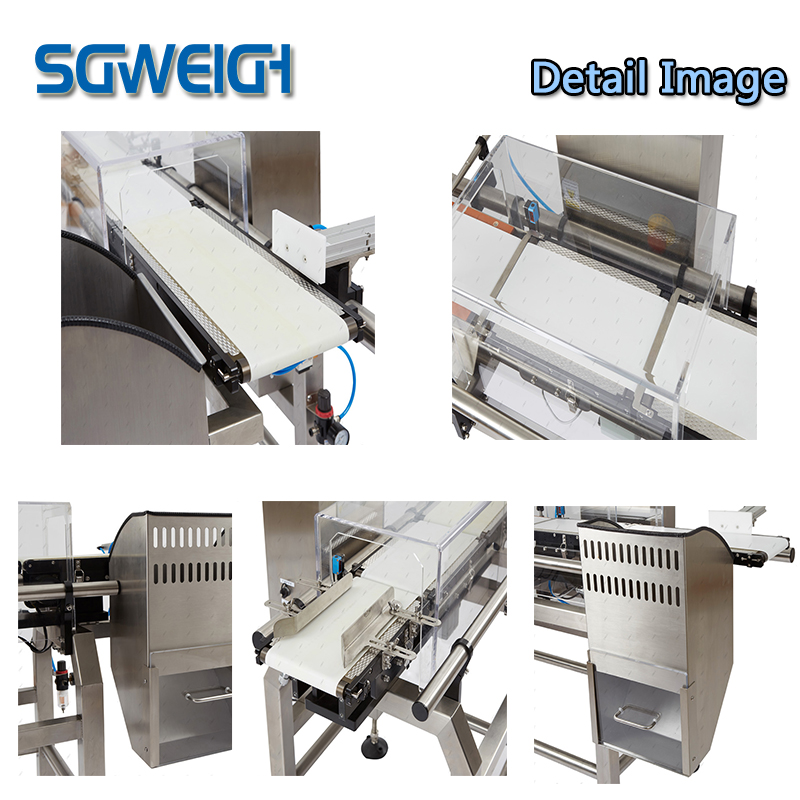

Product Details

Product Description

Conveyor Metal Detector with Touch Screen is a new generation of intelligent metal detection equipment developed by digital itechnology.The metal detection technology achieves fully digitalized and intelligent,with excellent performance and simple operation,Alarm Reject Metal Detector Machine greatly improve production efficiency of the enterprise.If you are interested in our products,please contact us !

Specification Parameter

Detection channel width (mm): 300-400 (customizable)

Detection channel height (mm): 100 (customizable)

Detection sensitivity: iron ball diameter (φmm) 0.6-0.8; 304 stainless steel diameter (φmm) 1.2; non-metal such as copper, aluminum and lead (φmm) 1.2

Alarm mode: buzzer, LED sound and light alarm, and automatic shutdown

Machine material: 304 stainless steel

Machine size: 1520*860*930MM

Machine weight: about 200kg

Power supply: AC220V 50-60Hz

Power: about 140W

Load capacity 5-25KG

Conveying speed: 24m/min (50Hz)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Main Advantages

· Metal contamination detection Detect all kinds of metal contamination, including ferrous, non-ferrous, and extremely difficult to detect non-magnetic stainless steel.

· Detect more metal phase adjustment technology to effectively suppress product signals; high-speed digital signal processing technology and intelligent algorithms.

· Satisfy product application Dual-frequency detection takes into account the detection sensitivity of dry/wet products.

· Stable and reliable Advanced automatic compensation technology ensures long-term stable performance.

· Customizable In addition to standard specifications, it can be customized according to different requirements of users.

· Efficient operation Automatic setting, fast switching of products, free product handling, historical data, multilingual operating system, etc.

Application

Metal detectors are suitable for many industries and fields such as food, pharmaceuticals, chemicals, textiles, clothing, rubber and plastics, toys, paper, sanitary products, electronics, and renewable resources.

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1. Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2. We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Customized Process

1st step:Customer has showed his special requirements.

2nd step:We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step:Making the conceptive CAD drawing based on communication and understanding.

4th step:Making the detail and 3D drawing agter fixed the design and other details.

5th step:Offer the quotation after confirm the design,material and surface treament.

6th step:Making the sample for approval.

7th step:Testing installation after demo mock up.

8th step:Big production delivery and service after sales.

Hot Labels