Product Details

Product Description

SG-Z High-Precision Turntable Checkweigher is used for automatic weight detection, upper and lower limit discrimination or weight classification and selection on various automated assembly lines and logistics conveying systems, and can also be used for product packaging and missing parts detection.Bottled Rotary Check Weight Machine can directly replace manual weighing, thereby protecting the customer's brand image and improving customer production efficiency and production quality.If you are interested in our products,please contact us!

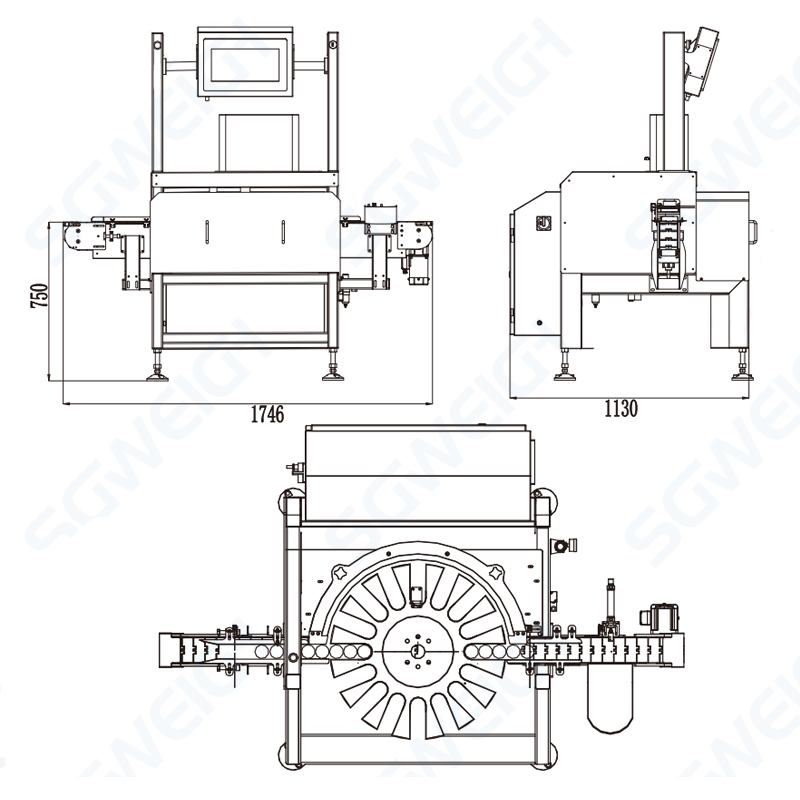

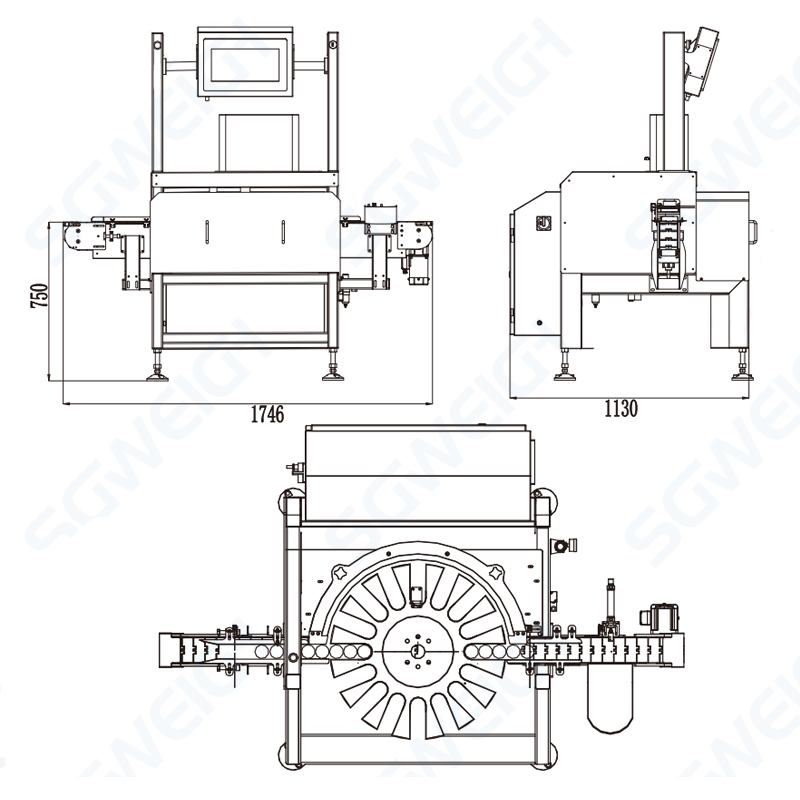

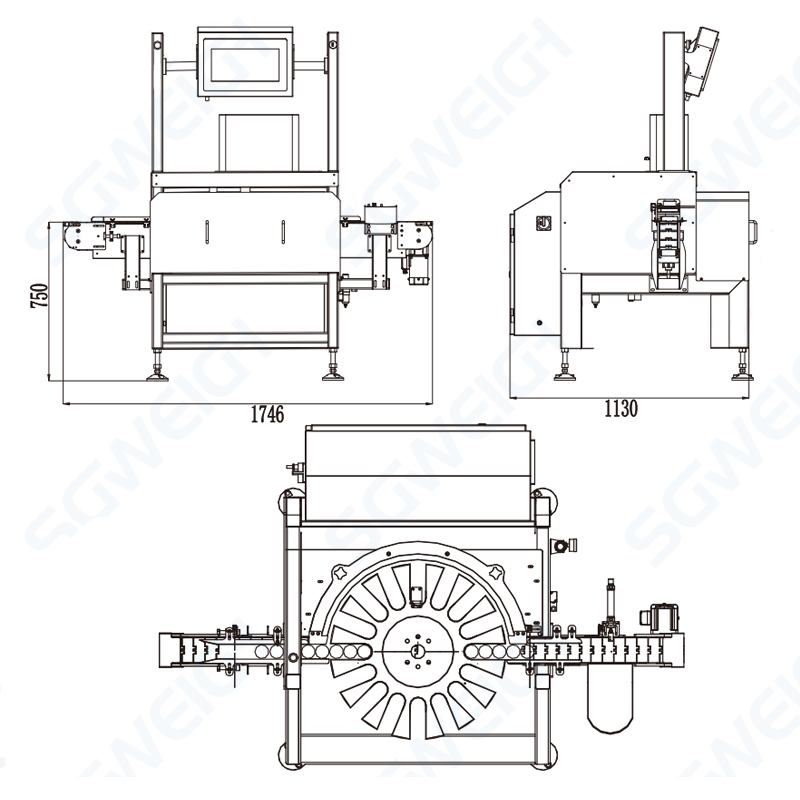

Specification Parameter

Model: SG-Z1

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting speed: up to 50 pieces/min (one channel)

Conveying speed: 20-100m/min

Operation mode: touch operation

Conveying direction: Facing the touch screen from left to right

Removal method: air blowing removal/push plate removal

Belt height from the ground: 750±50mm (can be customized according to customer requirements)

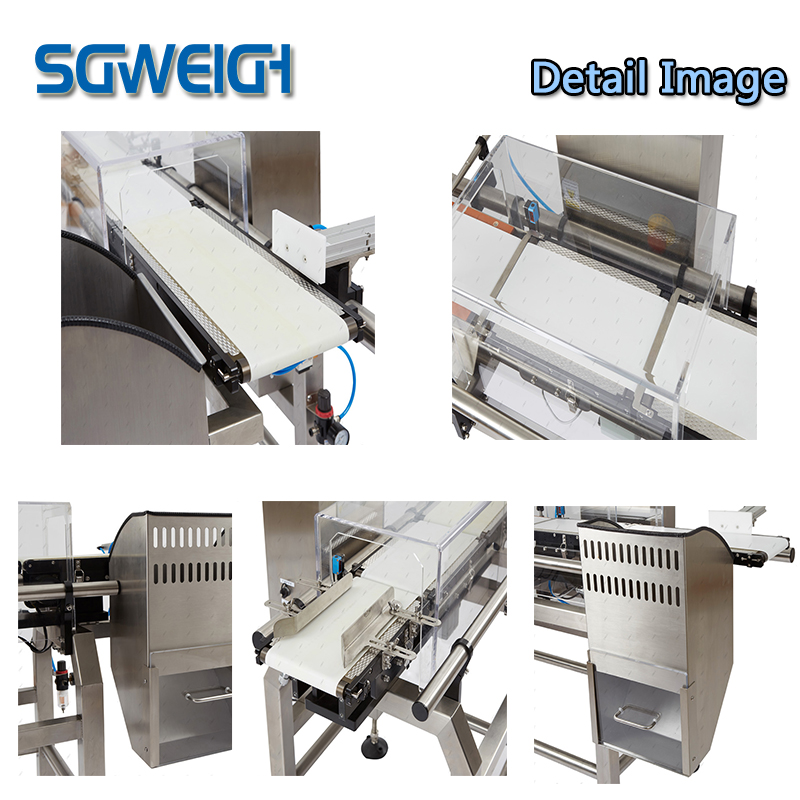

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power: about 300W

Windshield: thick acrylic (to avoid airflow interference)

Working environment: temperature: 0℃~40℃, humidity: 30%~95%

Remarks:The properties of the tested products and the use environment are different, and the detection speed and accuracy are also different. The actual test is the standard.

Working Principle

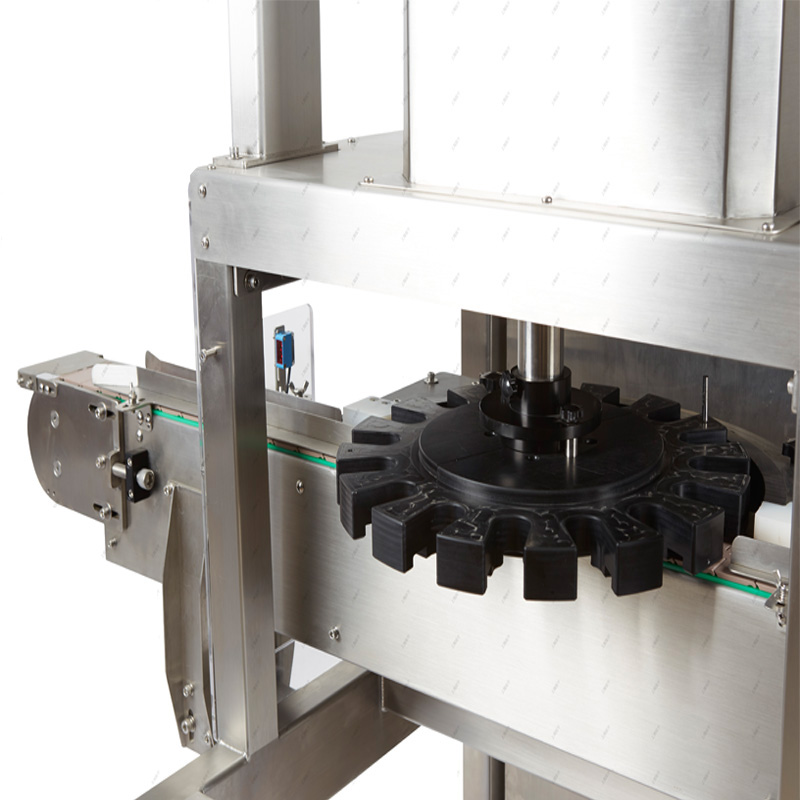

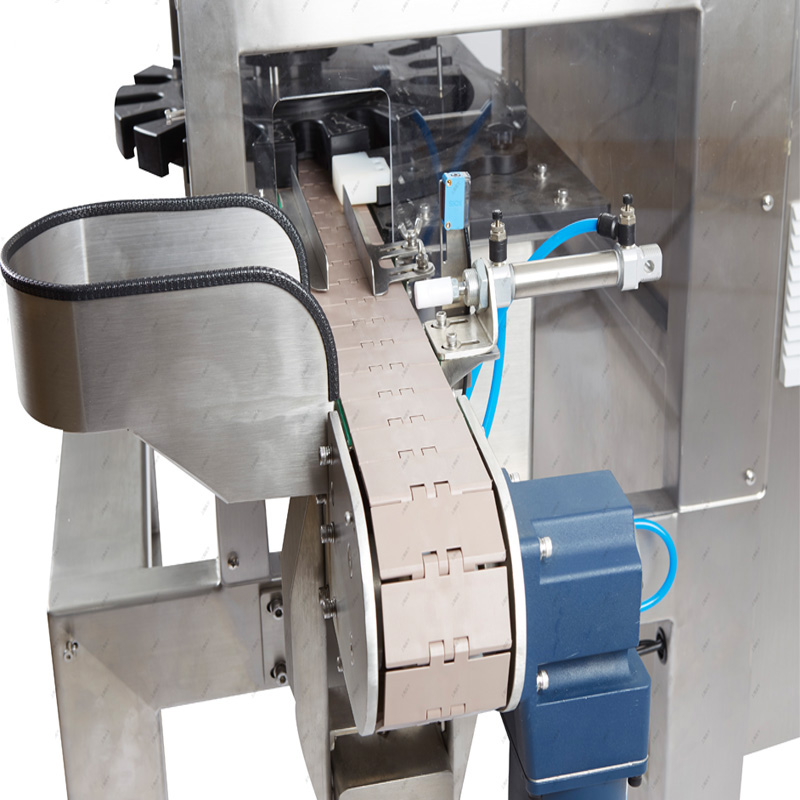

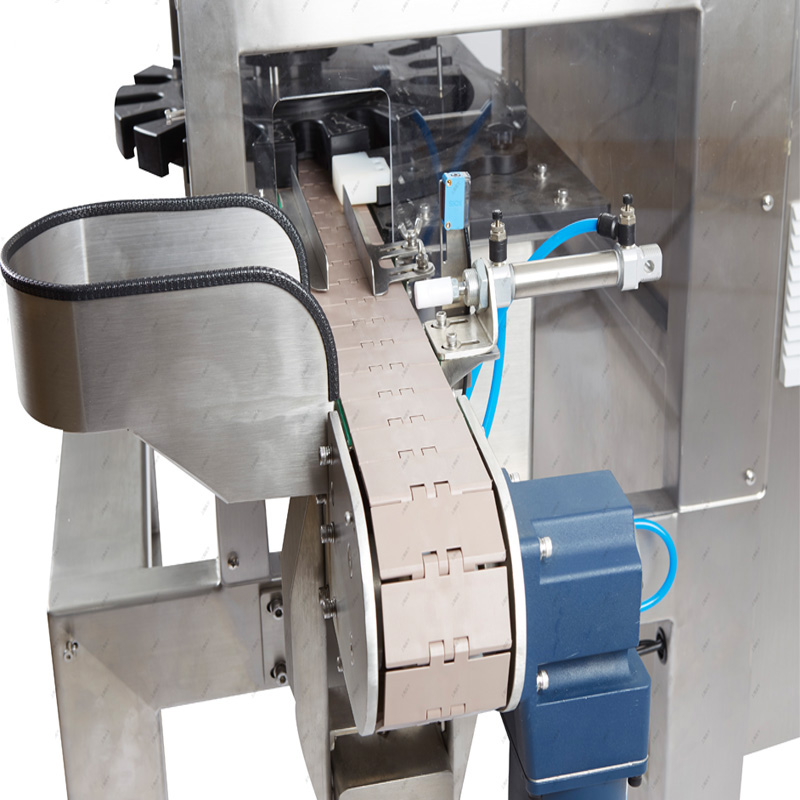

The turntable checkweigher is mainly composed of front-end chain plate feeding, clamping turntable, weighing module, discharge chain plate and rejecting.

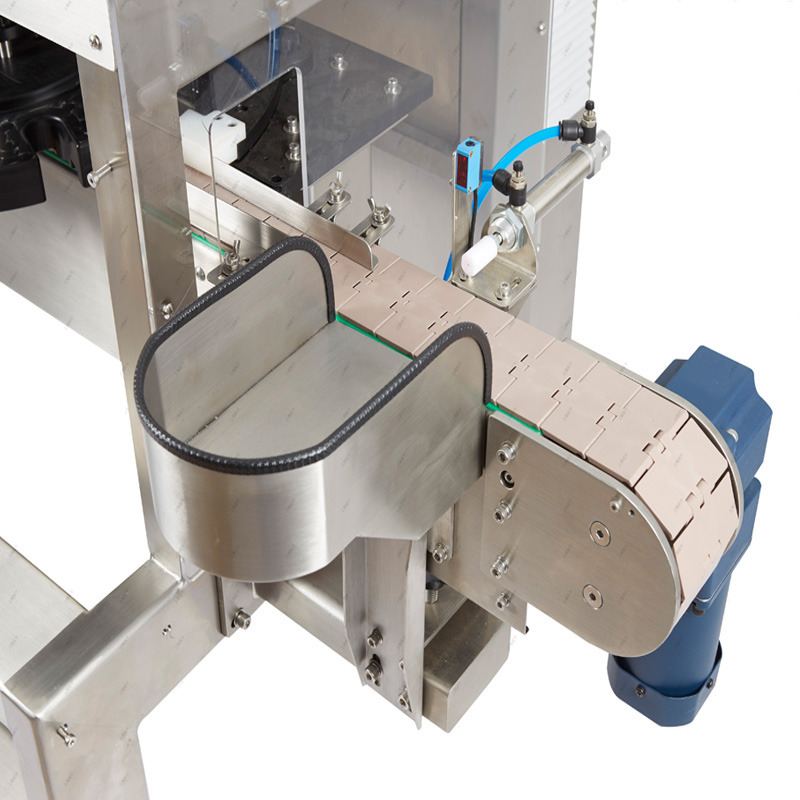

1.Front-end chain plate feeding:

The front-end feeding chain plate conveys the tested products to the turntable one by one through photoelectric induction.

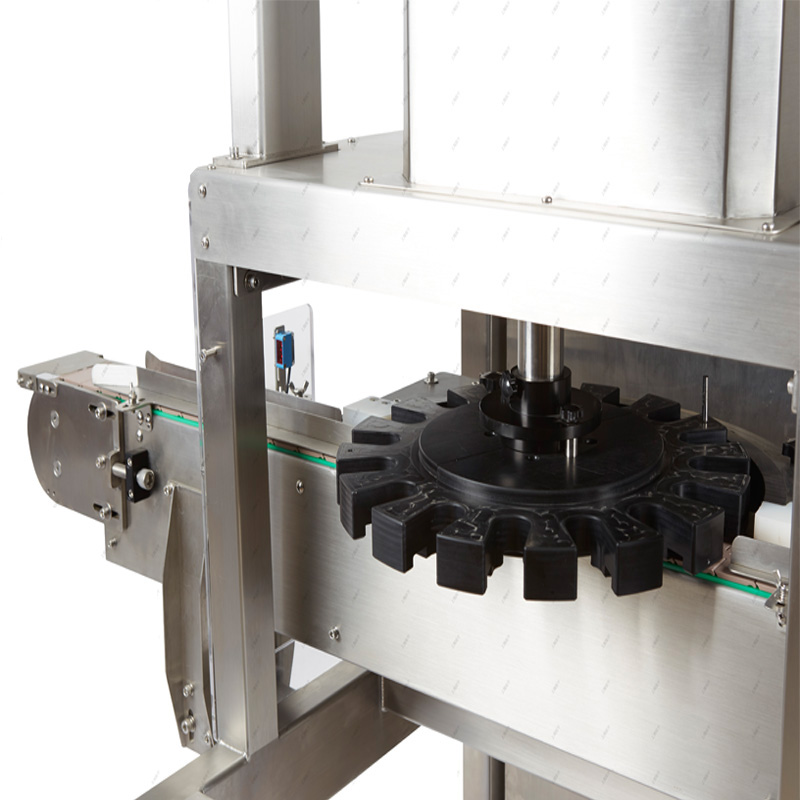

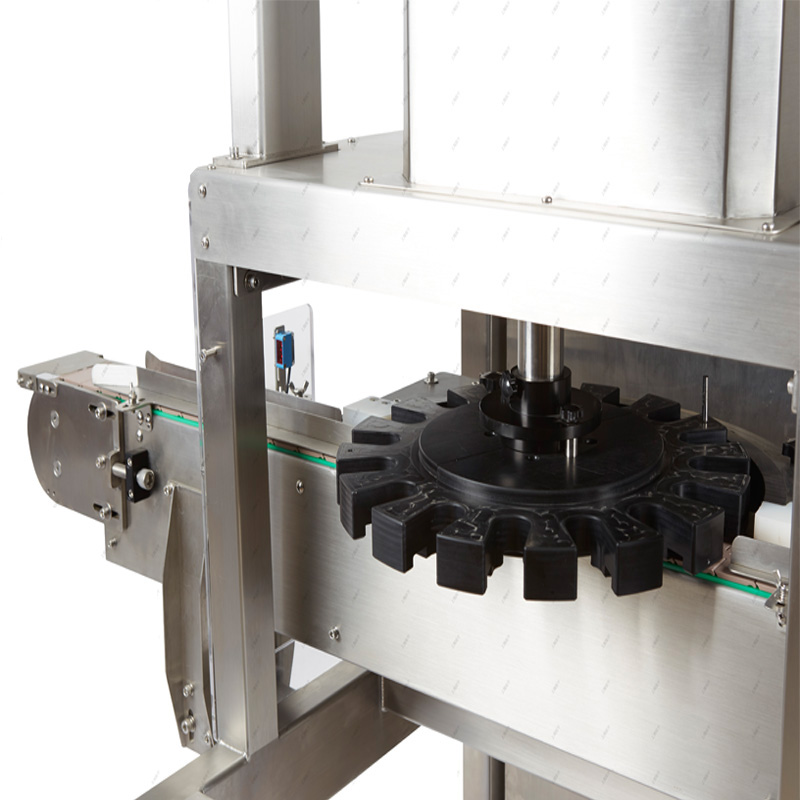

2.Clamping turntable:

Mainly clamp the corresponding quantity of products to the weighing module through the clamping turntable to ensure the accuracy of the quantity.

3..Weighing module:

Complete the collection of weight signals. When the measured product passes through the weight data of the weighing module to analyze and calculate all the weight data in the whole process, the weight of the

measured product is calculated. At the same time, the weighing module will judge whether the obtained weight data is in the within the desired weight range.

4.Rejection belt:

When the products pass through this section of the conveyor belt, the qualified products will continue to be conveyed backwards. If they are not within the required weight range, the machine will start the removal

mechanism to remove unqualified (overweight/too light) products.

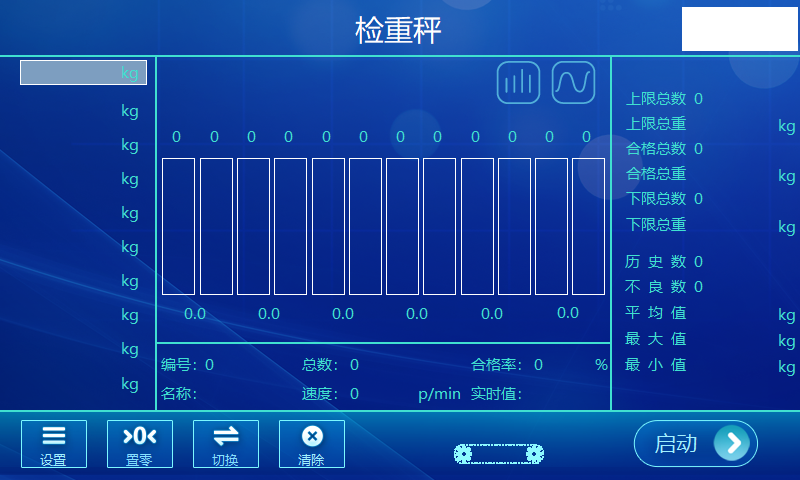

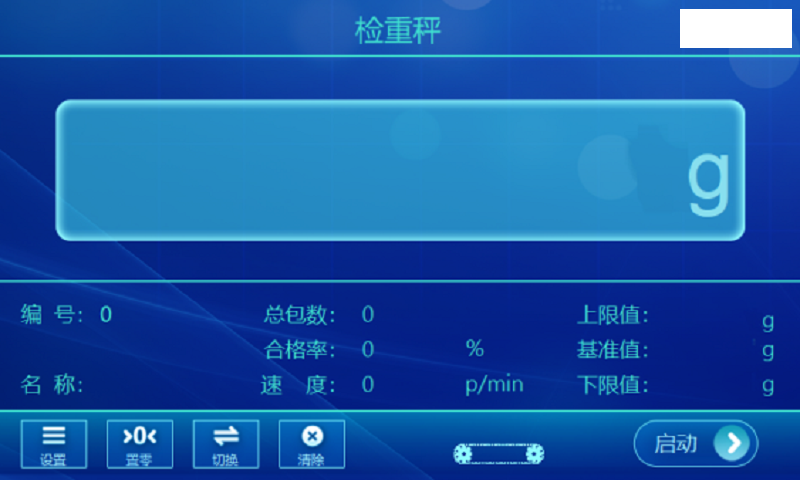

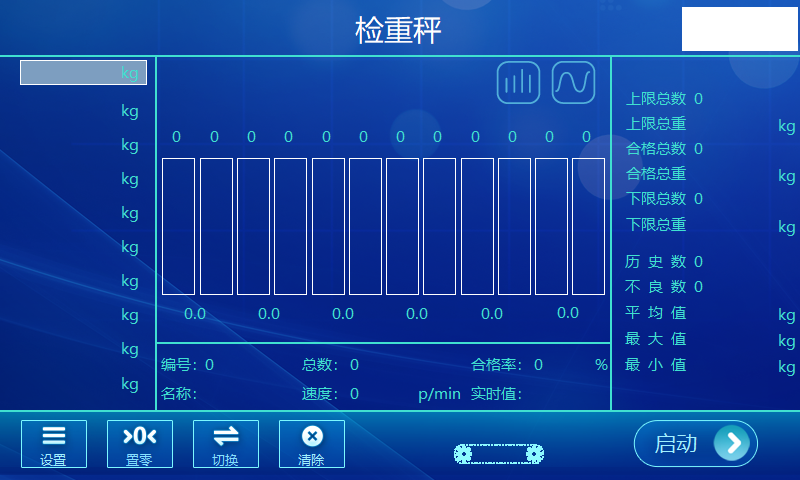

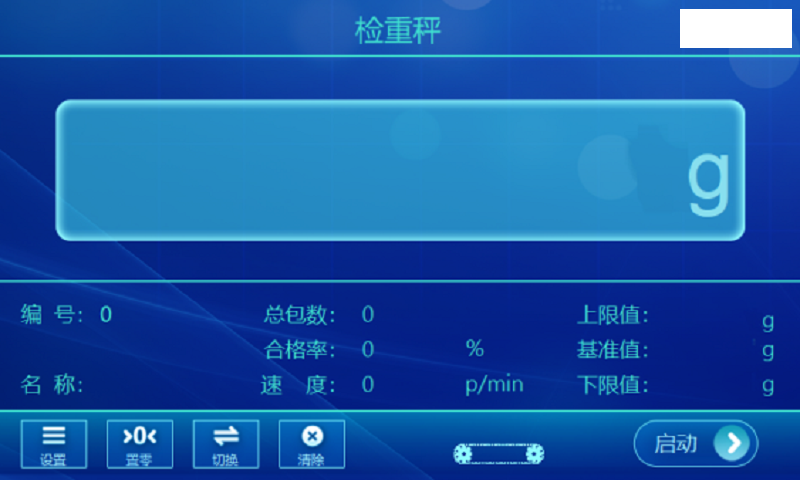

Operation Interface

The meanings of the buttons and signs on the interface:

1.Setting: enter the background, you can edit and modify each key value (upper and lower limits, reference value, name, number, speed, reject time, export/delete of weighing data, etc.). When the device starts running, the "Settings" button is unavailable, and it can only be used when the device is stopped, which is mainly used to protect personal safety.

2.Zero: Clear the current weight on the weighing platform and make the current weight the starting point (zero position).

3.Switch: switch between main running interface/statistical running interface.

4.Clear: Clear all statistical data of the current interface (background statistics data will not be cleared).

5.Start: Start/stop of conveyor belt.

6.Number: This equipment has 100 groups of formulas that can be set and saved. Different product standards can be set and saved under different numbers. The corresponding number can be directly called next time.

7.Name: different numbers can be set without a name, which is convenient for recording. The name is composed of numbers and letters.

8.Total number of packages: the passed quantity under the current batch.

9.Pass rate: the ratio of the total quantity to the unqualified quantity under the current batch.

10.Speed: The number of current batches passed in a recent period of time.

11.Upper limit value: the maximum value allowed by the current product weight. When the weight of the product passed is greater than the upper limit value, the actual weight value will be displayed in the upper frame and the background color will be red.

12.Benchmark value: the standard value of the current product weight. When the product passes through, the actual weight value is displayed in the upper frame and the background color is blue.

13.Lower limit value: the minimum value of the current product weight that is allowed to pass. When the weight of the passed product is less than the lower limit value, the actual weight value will be displayed in the upper frame and the background color will be yellow.

14.Remarks: When the conveyor belt is stopped, the weight displayed in the big frame is the real-time weight. When the conveyor belt is running, the weight displayed in the large box is the weight value of the previous product, and the value will only change when the product passes through again.

The latest 10 weight values are displayed on the left, and the data is updated sequentially from top to bottom. After clicking the clear button, the value is cleared to zero.

Real-time value: Displays the actual weight value sensed by the current scale.

Total Upper Limit: The total quantity that exceeds the upper limit value.

Upper limit total weight: the weight accumulation value exceeding the upper limit value.

Qualified total: the total quantity within the upper and lower limits.

Qualified gross weight: the cumulative weight value within the upper and lower limits.

Lower Limit Total: The total quantity below the lower limit value.

Lower limit total weight: the weight accumulation value lower than the lower limit value.

Historical number: the total quantity of this batch (the total number of the upper limit + the total number of qualified + the total number of the lower limit).

Defective number: the total number of unqualified products in this batch (the total number of upper limit + the total number of lower limit).

Average: The average of the total quantity of this batch.

Maximum value: the maximum value that appears in the total quantity of this batch.

Minimum value: The minimum value that appears in the total quantity of this batch.

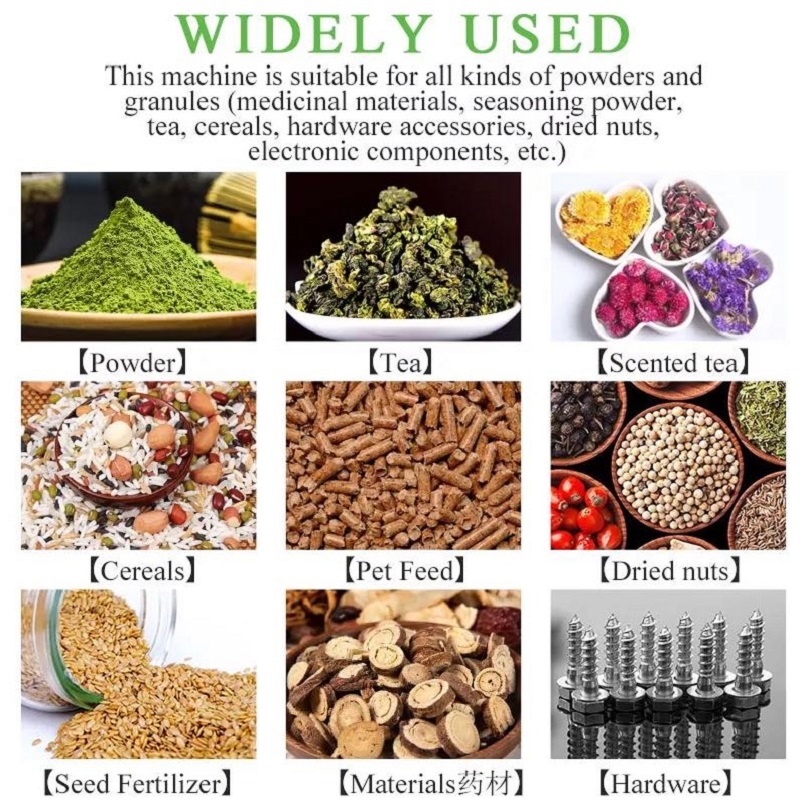

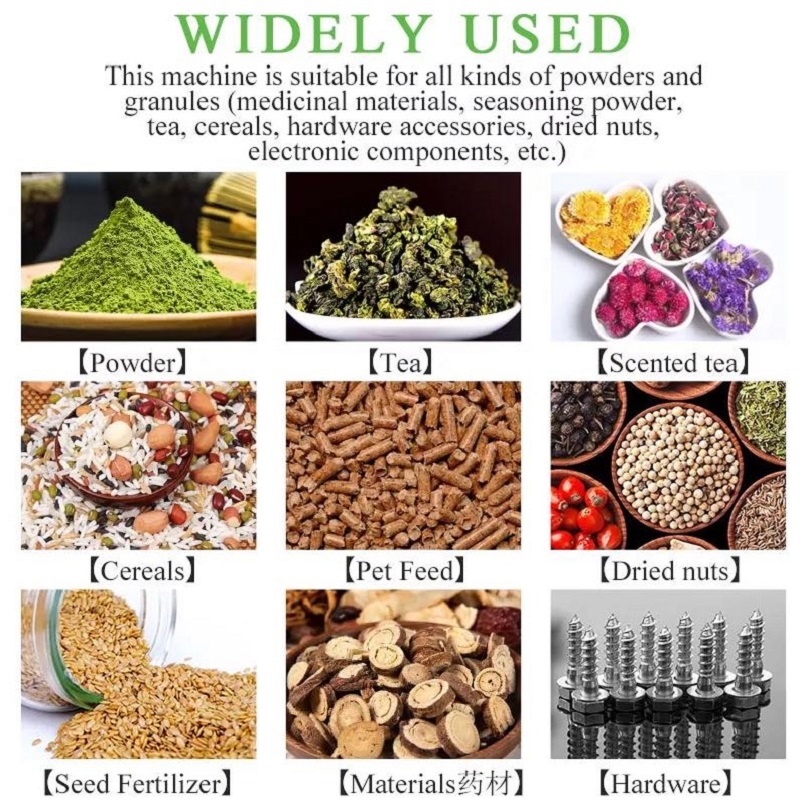

Application

Our Customers

Our Exhibitions

Package & Shipping

Our products can be shipped by sea, air and land.

After Sale Service

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial Co,.Ltd solemnly promises you with the principles of preferential prices, considerate service and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo