Product Details

Product Description

SG-450 Intelligent Check Weight Machine can weigh and check various weights online,and identify the corresponding abnormal weight of the product.The checkweigher provides professional customized solutions according to the user's product characteristics and application scenarios.The Drum Type Automatic Checkweigher is suitable for boxed/bagged/bottled/canned products,and is not limited by the packaging material,and can be accurately checked in various shapes.If you are interested in our products,please contact us !

Specification Parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you !

Main Advantages

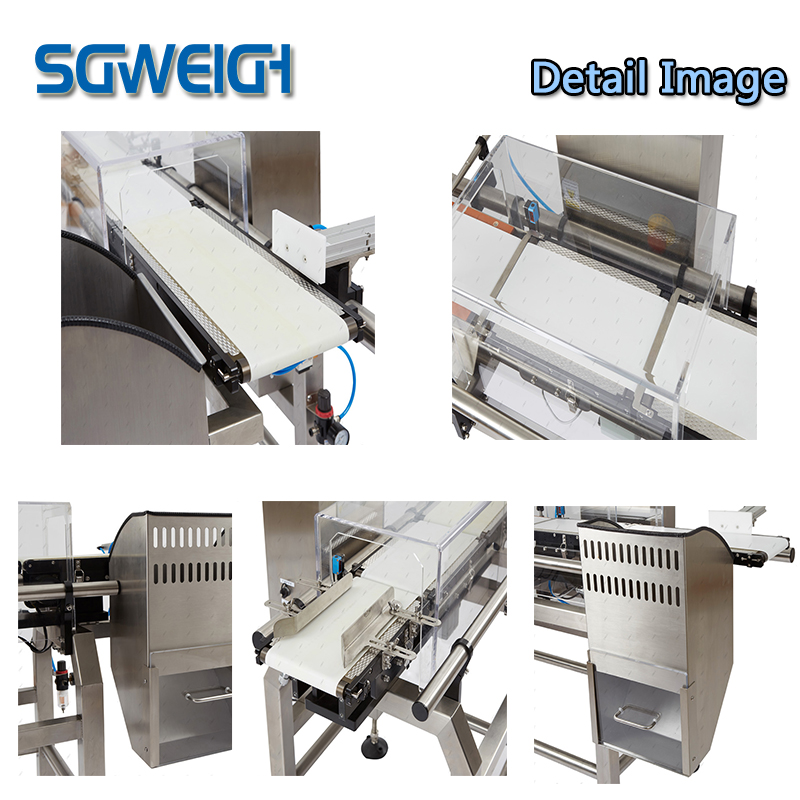

Practical

7/10-inch high-color, high-resolution man-machine interface, easy to operate and friendly, easy to use. A variety of product preset functions, one-click replacement of product parameters.

high stability

Independent research and development of weighing identification algorithm, automatic dynamic zero point tracking and anti-vibration algorithm, weighing data identification is faster and more stable. It has a power-off memory function to prevent the weighing data from being lost in the event of a sudden power failure or trip in the factory.

Convenient Docking

Counterweight data storage and export function, which can store multiple product weighing information, and export EXCEL table data from U disk; can realize docking with EMS, WMS and other systems, product information traceability, remote control equipment start and stop, multiple data verification mode , to ensure that the data is not leaked.

Rigorously Designed

Modular structure, easy to disassemble, easy to maintain, easy to clean.

Cost-Effective

Different casing materials, sensors and other standard parts can be customized according to the actual needs of customers.

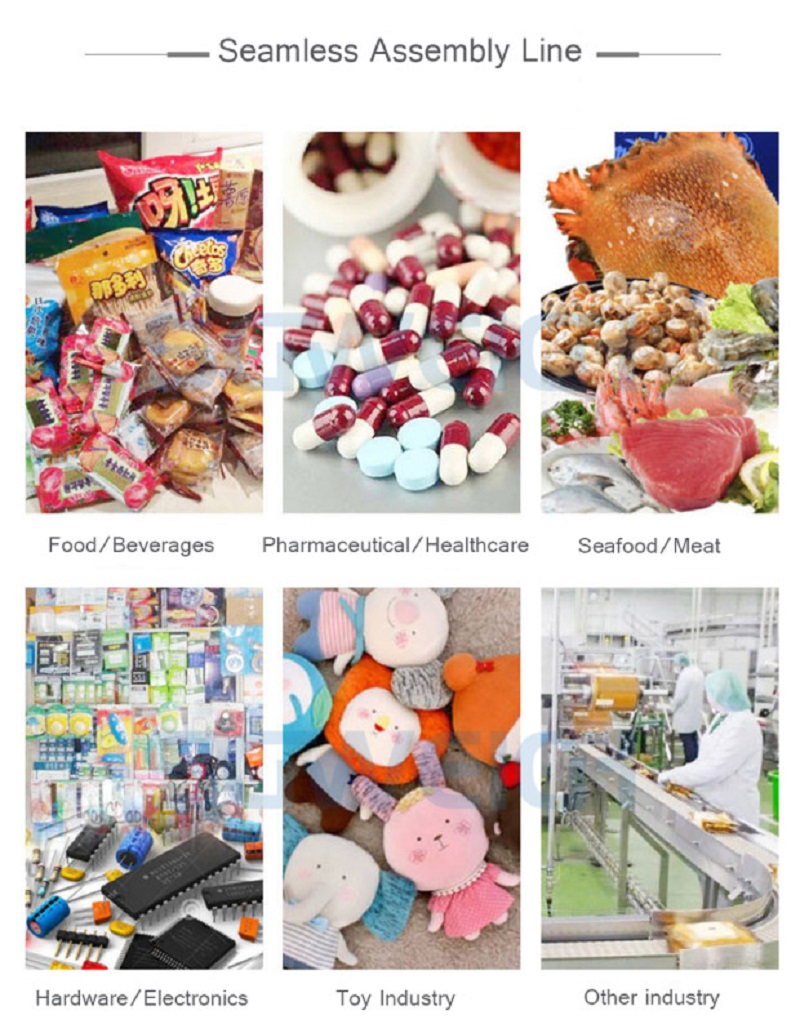

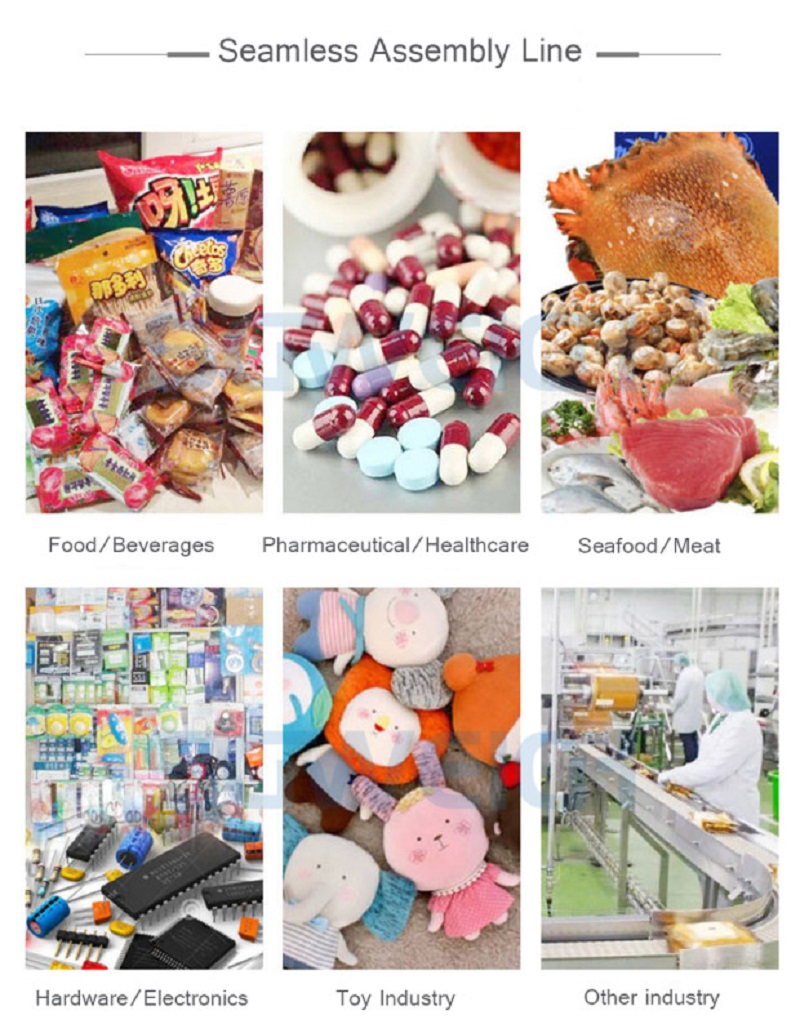

Application

Food

The automatic dynamic check weighing machine can solve the detection of insufficient/overweight net weight of packaged food, full box/full bag/full box/complete package missing of packaged food

the medical

The high-precision checkweigher can solve the problem of detecting whether there are few or many tablets in the pharmaceutical industry; whether the powder bagged medicine is missing or has multiple bags; whether the weight of the liquid medicine meets the standard requirements; whether the drug accessories are missing wait).

Cosmetic

Checkweighers solve quality control problems for automatic weighing and inspection of packaging lines. Detect whether the mask is missing, whether the bag is missing, whether the cosmetics meet the production requirements, whether the product is complete, etc.

Daily Necessities

The checkweigher is used to detect the missing quantity of single items in products such as bags, bags, boxes, bottles, cans, boxes, etc.

Hardware

The online checkweigher can detect various metal stamping parts, die-casting parts, processed parts, precision parts, spare parts and other product quality inspections, and online weighing and classification of building materials products.

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1. Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2. We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

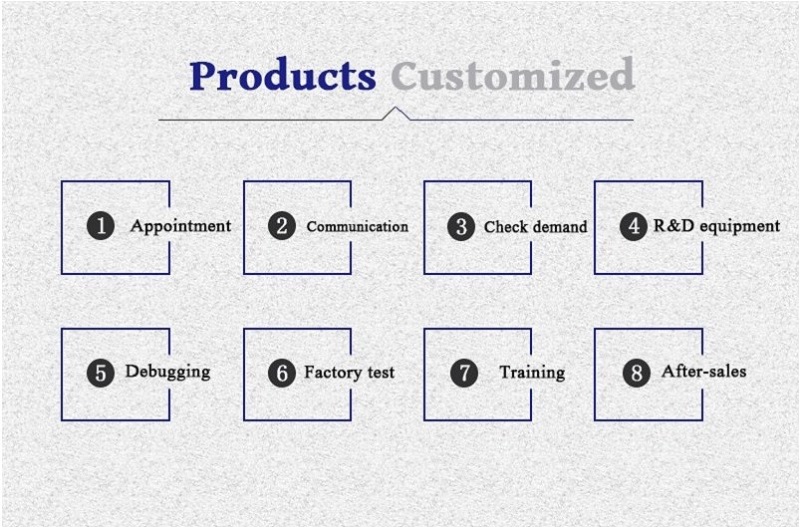

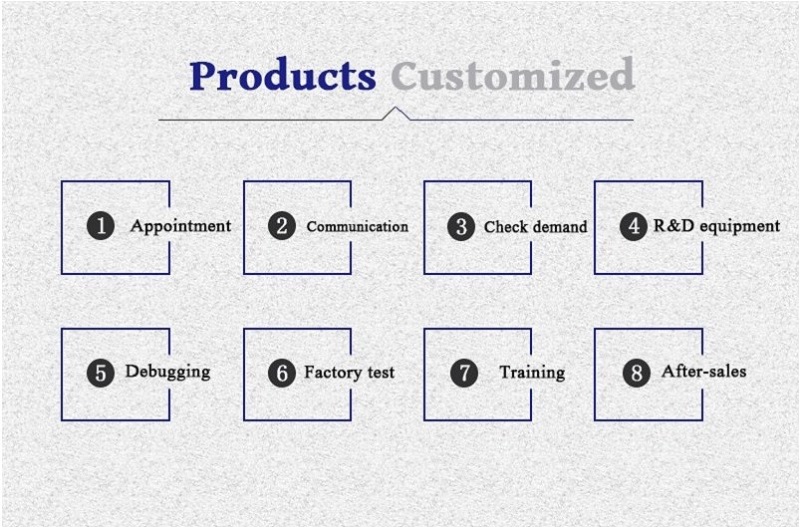

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.

Kindly remind

Please let us know the follow packing details when you need, so that we can check if this model is suitable for your case.Thank you in advance.

●Product details.

●Bag Width, Bag Length. (Similar Picture)

●Bag Shape.

●Packing film material.

●Machine frame.

Hot Labels