Product Details

Product Description

The Multifunctional Weighing Metal Detection Integrated Machine is characterized by detecting weight and metal impurities at the same time.One machine is multi-functional,helping food processing enterprises to automatically detect different situations such as qualified products, unqualified products, missing products, and products containing metal impurities.The unqualified products under the control system will automatically remove the unqualified products to ensure the integrity and quality assurance of the ex-factory products.If you are interested in our Food Industry Intelligent Weigh Combined Metal Detector,please contact us!

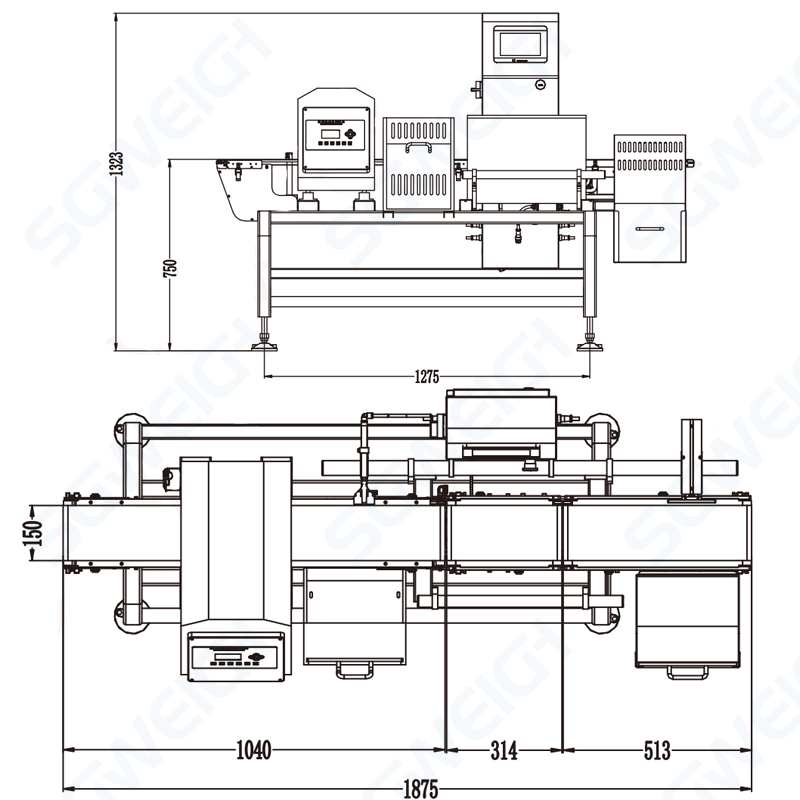

Specification Parameter

Detection method: electromagnetic induction / digital load cell

Size: 330×150mm

Accuracy: FE0.8mm SUS2.0mm

Sorting accuracy: ±0.5 grams

Weighing range: 5g-900g

Through height: 110mm

Through width: 280mm

Packing length: ≤300mm

Display division value: 0.1g 0.2g 0.5g 1g

Sorting segment number: 3 segments

Sorting capacity: 60 times/min

Conveyor belt speed: 10-45 m/min

Height from the ground: 735mm—800mm

Working temperature: 0-40℃

Weight: about 160 kg

Dimensions: 1900mm×700mm×1120mm (L×W×H)

Main Advantages

1. Reverse detection

It adopts high-precision imported through-beam switch and cooperates with the curve fitting algorithm to accurately complete the reverse detection.

2. Customization ability

It can be equipped with a scanning gun to meet various special requirements for deep customization and functional development.

3. Easy and intelligent operation

With wide LCD and wizard interface, users can easily set up and operate.

4. Reliable data

Use FRAM storage technology to ensure system parameters and data.

5. Advanced manufacturing technology

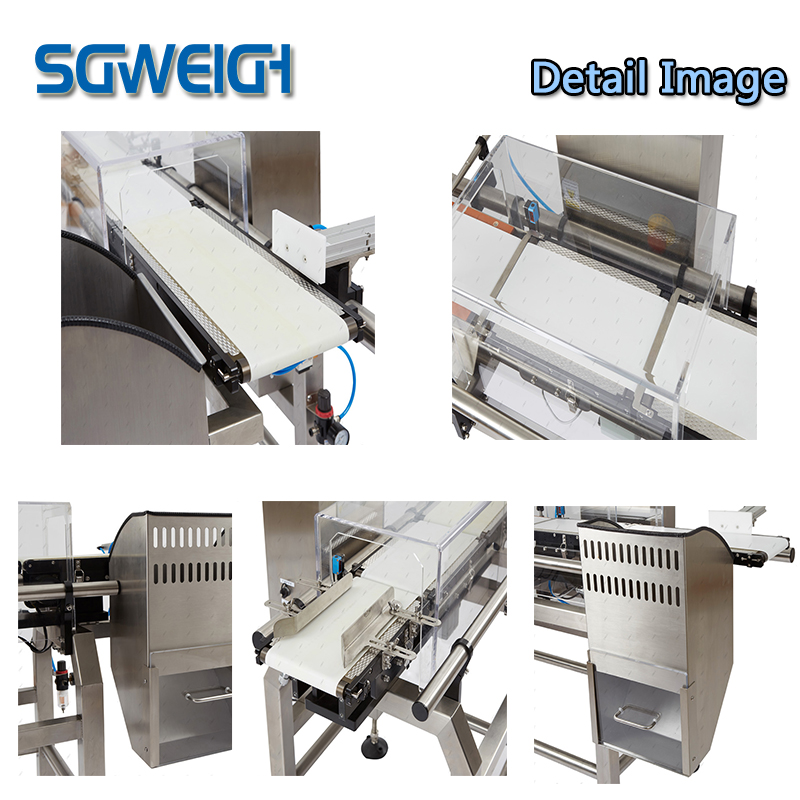

The metal detector adopts all stainless steel probes and frames, and various protection levels are available for customers to choose, adapting to various production environments.

6. Conveyor belt anti-deviation design

The metal detector adopts a special conveyor belt anti-deviation design scheme to effectively avoid the deviation of the conveyor belt.

7. Abundant peripheral interfaces

RS-485 data communication, PLC programming nodes, and printer output can be configured, which can provide real-time data for the production management system for remote control, analysis and monitoring,and provide valuable traceability information.

8. Rejecting device

Equipped with blocking arm type, blowing type, flap type, push rod type and other rejecting devices.

Application

Our Customers

Our Exhibitions

Package & Shipping

Our products can be shipped by sea, air and land.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo