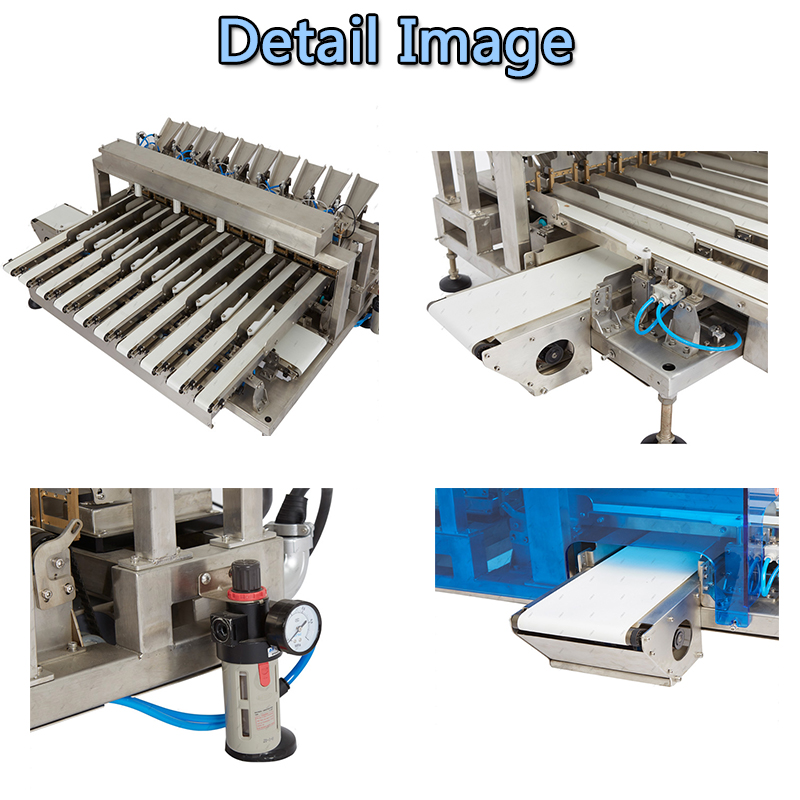

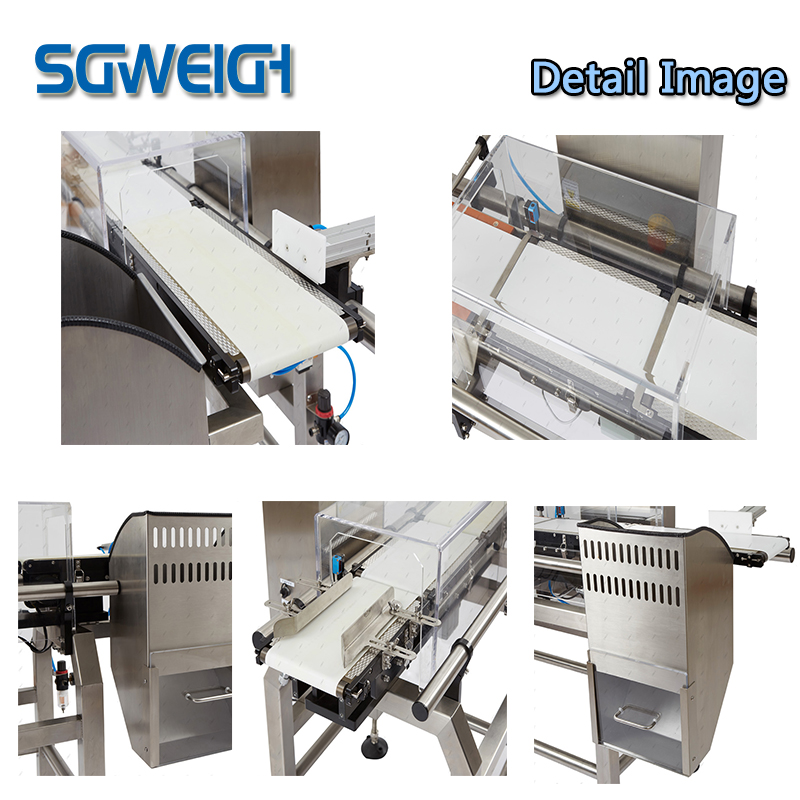

Product Details

Product Summarize

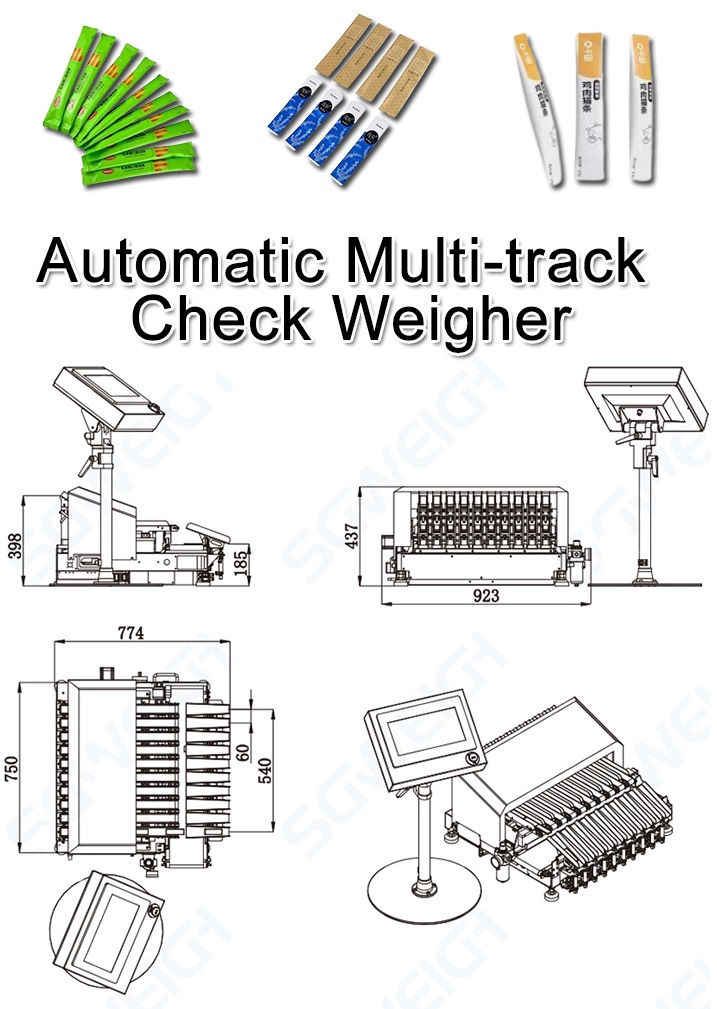

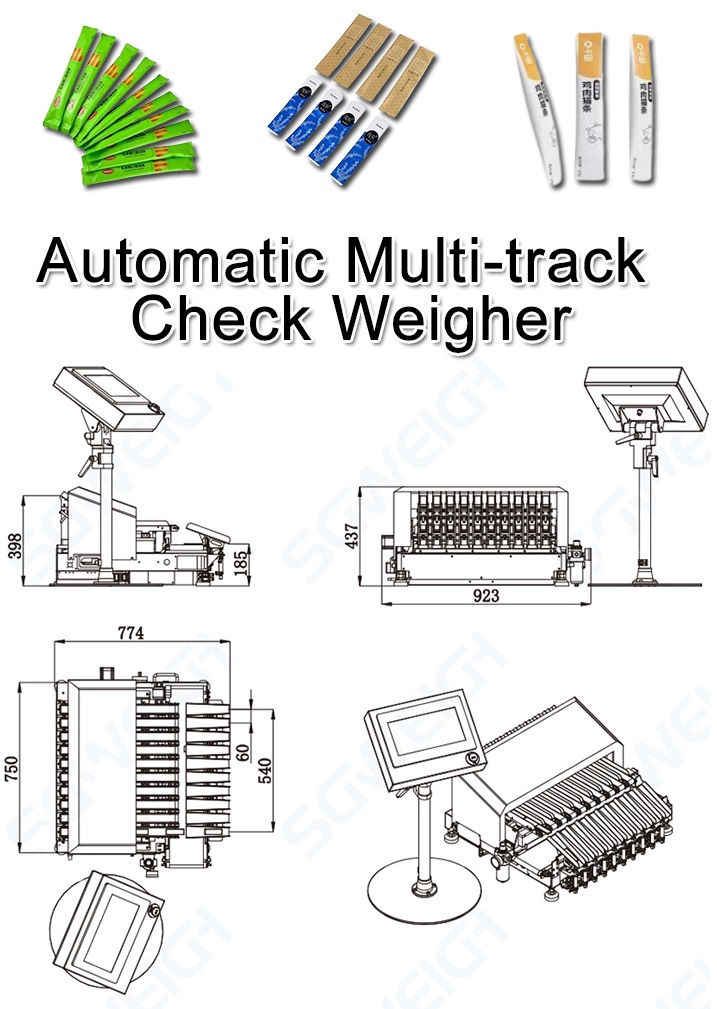

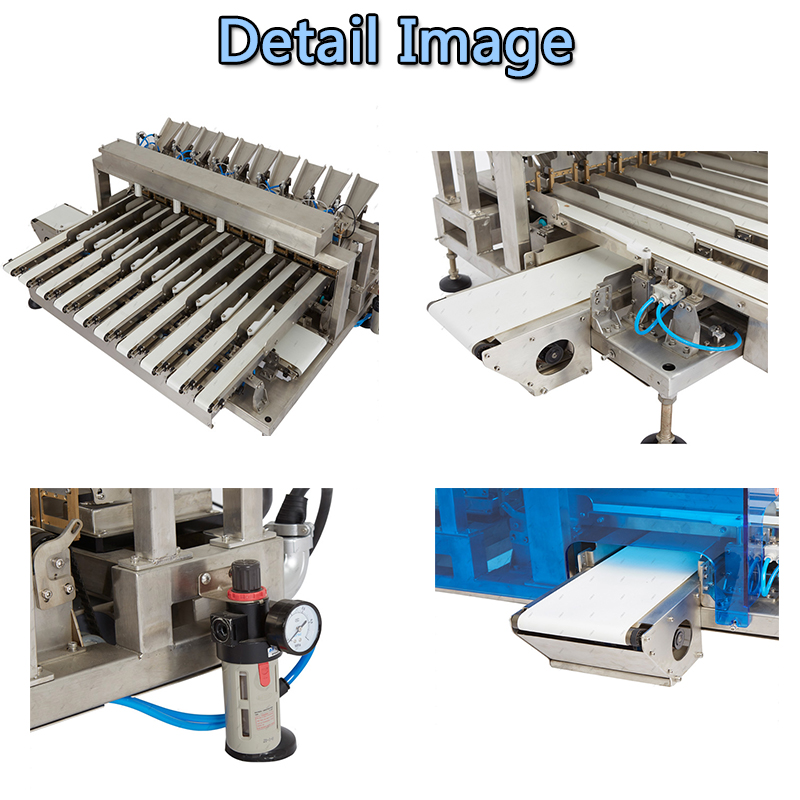

SG-10XM High Accuracy Automatic Multi-track Check Weigher is an advanced industrial machine used to check the weight of multiple products simultaneously on a production line. It is a special type of checkweigher designed to handle product passing through multiple lanes or tracks of a weighing station.This type of checkweigher is particularly useful in high-speed production environments where efficiency and accuracy are critical.Welcome to consult for quotation information !

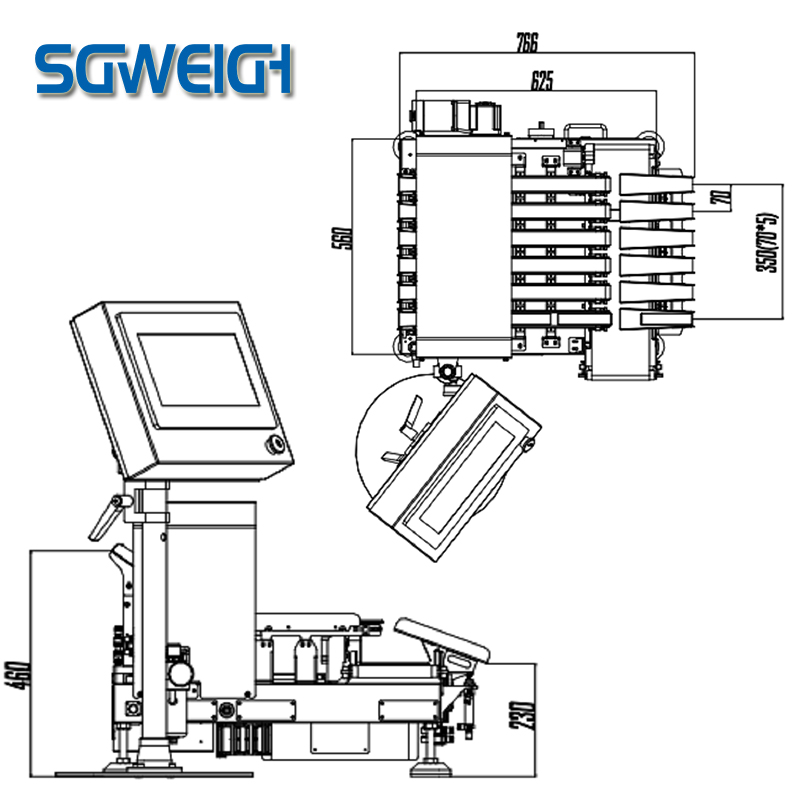

Product Parameter

Type:SG-10XM

Weighing scope: 2-300g

Restrictions of product:L:180 W:40 H:2-20(mm)

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt width:30mm

Highest speed:70pcs/min(one lane)

Weight of machine:about 200Kg

Powder supply:AC220V 50HZ

Power:about 300W

Main material:SUS304(Stainless Steel)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

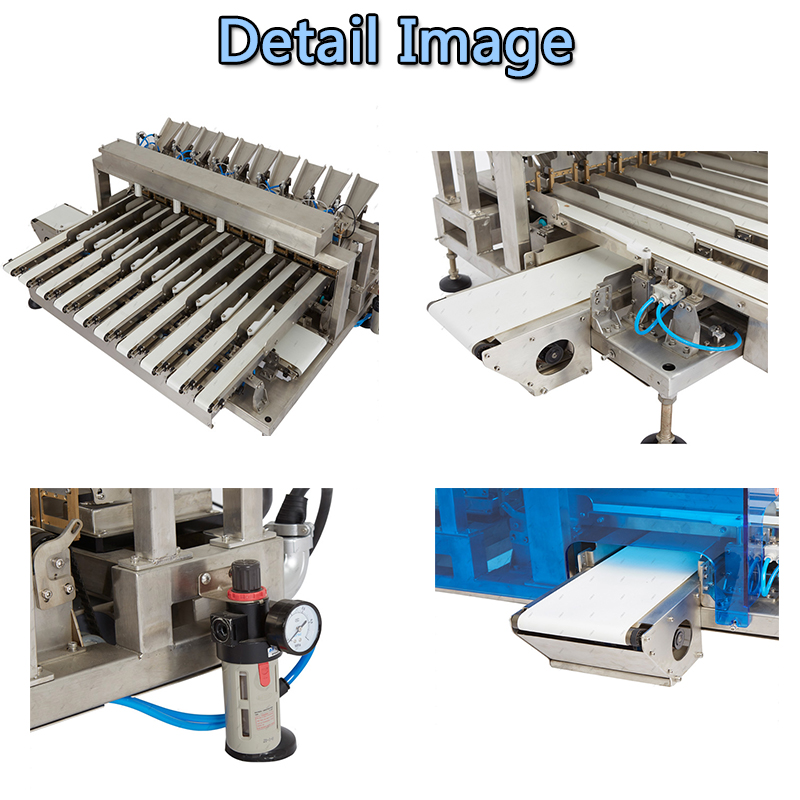

Product Characteristics

1. It is suitable for multi-row simultaneous automatic weight detection of small packaging products such as food, medicine, and daily necessities

2. Greatly improved the detection speed per unit time

3. Effectively prevent empty bags, underweight, overweight and other defective products

4. Count the passed products, and automatically remove unqualified products by the sorting device

5. It can be matched with multi-column packaging machines, automatic filling machines, metal detectors, etc.

6. Customized according to the requirements of the on-site production line, and can be configured with automatic barcode scanning and inkjet system

7. The number of detection columns can be customized according to customer needs (such as double columns, four columns, six columns, ten columns, etc.)

8. Each channel can eliminate unqualified products separately.

9. The number of consecutive unqualified products in each channel can be modified.

10. Statistical data of each channel: real-time result display, trend graph display, and histogram display.

Specific Application

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

A. Pre -sale:

1. In accordance with the customer's requirements, the customer quotes the customer, and the customer has special requirements for timely recording feedback;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide free warranty for one year, lifelong maintenance service, and be responsible for debugging the product before delivery;

B. After -sales:

1. If the customer's product fails, the problem will be solved for you as soon as possible

2. During the warranty period, the product maintenance is free. It exceeds the warranty period and can also provide maintenance. If the accessories are replaced, the product accessories are provided at the cost price.

Hot Labels

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher

Weigh Labeling Machine