Product Details

Product Description

Automatic Online Weighing Printing Checkweigher is mainly used for weighing the product itself on the automatic assembly line, printing labels containing real-time weight information, and performing real-time labeling.High Speed Desktop Weigh Labeling Machine can replace manual weighing, printing and labeling. This improves production efficiency and the consistency and reliability of weighing, printing and labeling. Widely used in food, medicine, daily chemical, industrial manufacturing, printing, logistics and other industries.Welcome to consult for quotation information !

Specification Parameter

Weighing range: 5g—1500g

High detection accuracy: ±0.5 grams (the greater the weight, the faster the speed, the worse the accuracy, depending on the product size, speed, and weight)

Minimum scale: 0.1g

Belt width: 220mm

Belt height from ground: 800mm±50mm

Conveying speed: 20-60 m/min (variable frequency speed regulation)

Detection speed: 60~120 pieces/min

Conveying direction: facing the screen from left to right

Power supply: 220V 50-60HZ

External air source: 0.6—1Mpa

Air pressure interface: ¢8mm

Power: about 200W

External dimensions: about 1543mm(L)*721mm(W)*1470±50mm(H)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Main Advantages

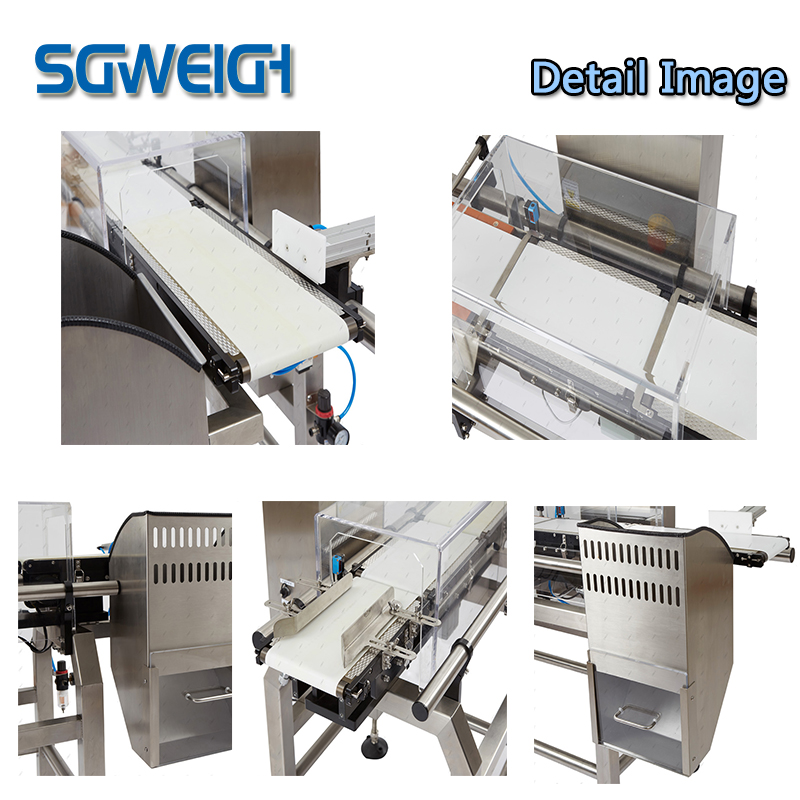

1. The labeling machine is durable

The moving guide rod of the labeling head adopts double rods and ball bearings, so it ensures the high precision of labeling and the durability of the labeling machine.

2. Suitable for barcode printing and labeling of products of different heights

Through the automatic induction adjustment control of the cylinder stroke, it can easily automatically sense and label products of different heights. It can be attached to the bottom, side, and arc surface.

3. Easy to adjust

Adjust the gap between the labeling head and the edge of the label through four screw adjustments, and use the TEST mode to adjust with one key on the keyboard to optimize the entire printing and labeling process.

4. Compressed air unit

Installed next to the printer, by adjusting the valve to ensure the quality of labeling, the flow rate is less than 2CFM.

5. High flexibility

Tthe labeling method can be selected according to the characteristics of the product. Blowing labeling can label circular and irregular products.

6. Strong real-time performance

Barcode sticky notes, the content can be printed immediately from the company's ERP system and weighing system.

7. Open signal transmission system

USB keyboard and barcode scanner can be connected.

Application

Our Customers

Our Exhibitions

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

1.Product quality commitment

(1). There are quality records and testing data for the manufacture and testing of products.

(2). For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and

shipped.

2. the product price commitment

Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment

Product delivery time: as far as possible according to user requirements, if there are special requirements, it needs to be completed in advance, and strive to meet user needs.

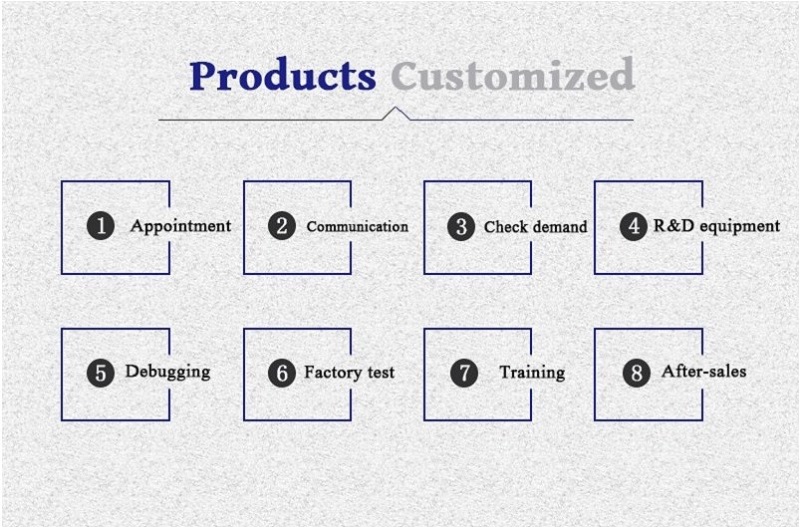

FAQ

1. Can your machine meet our needs well?

A: After receiving your inquiry, we will confirm your weight per bag, labeling speed, bag size (this is the most important). Then advise you according to your

specific requirements. Each machine is custom made to meet your needs.

2. Are you a factory or a trading company?

A: We are a factory with more than 13 years of experience.

3. How to confirm the quality of the machine after placing an order?

A: Before shipment, we will send you pictures and videos for you to check the quality, you can also arrange for the quality to be checked by yourself or your

contact in Shanghai.

4. What are your packing conditions?

A: Usually, we pack our goods in wooden boxes.

5. How about your delivery time?

A: Generally, it takes 15 to 45 days after receiving your advance payment. The exact delivery time depends on the item and quantity you ordered.

Hot Labels

Food Checkweigher

PharmaceuticalCheckweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo