Product Details

Product Introduction

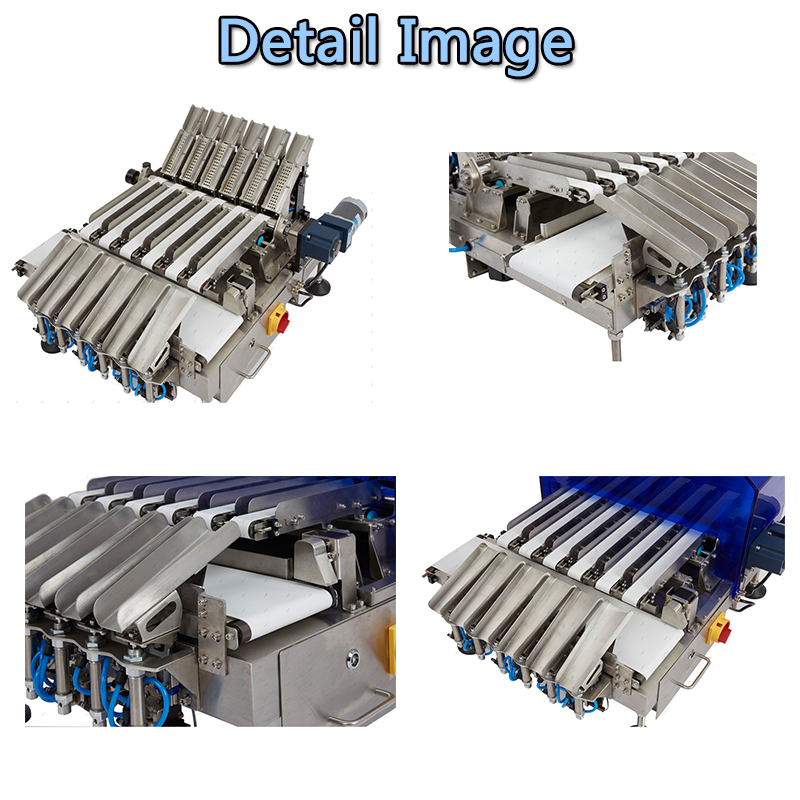

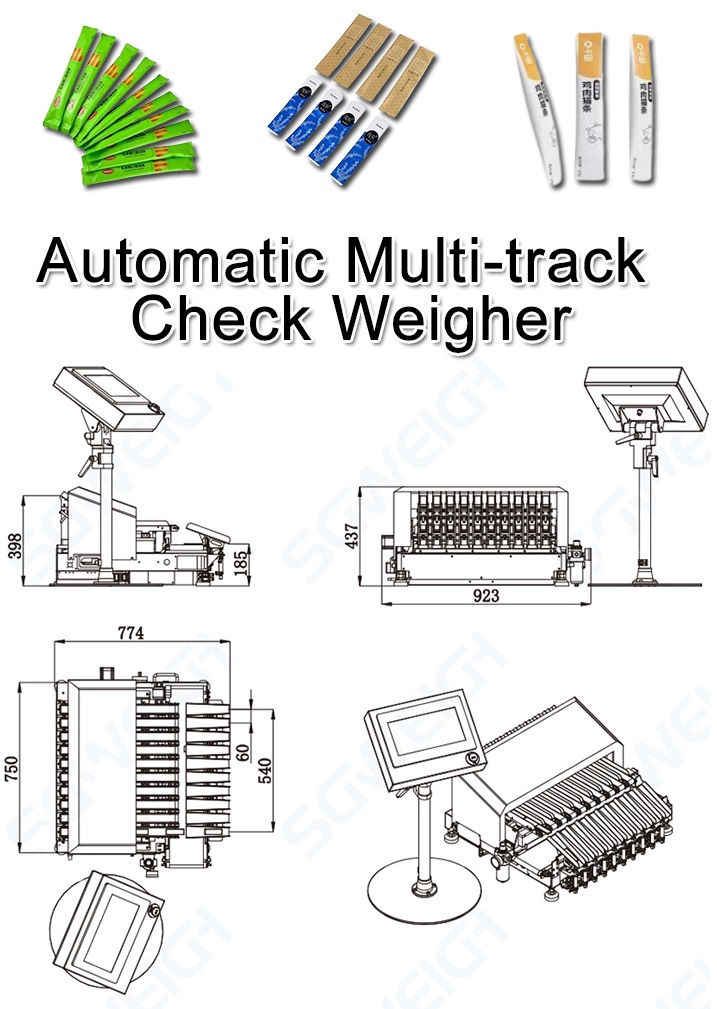

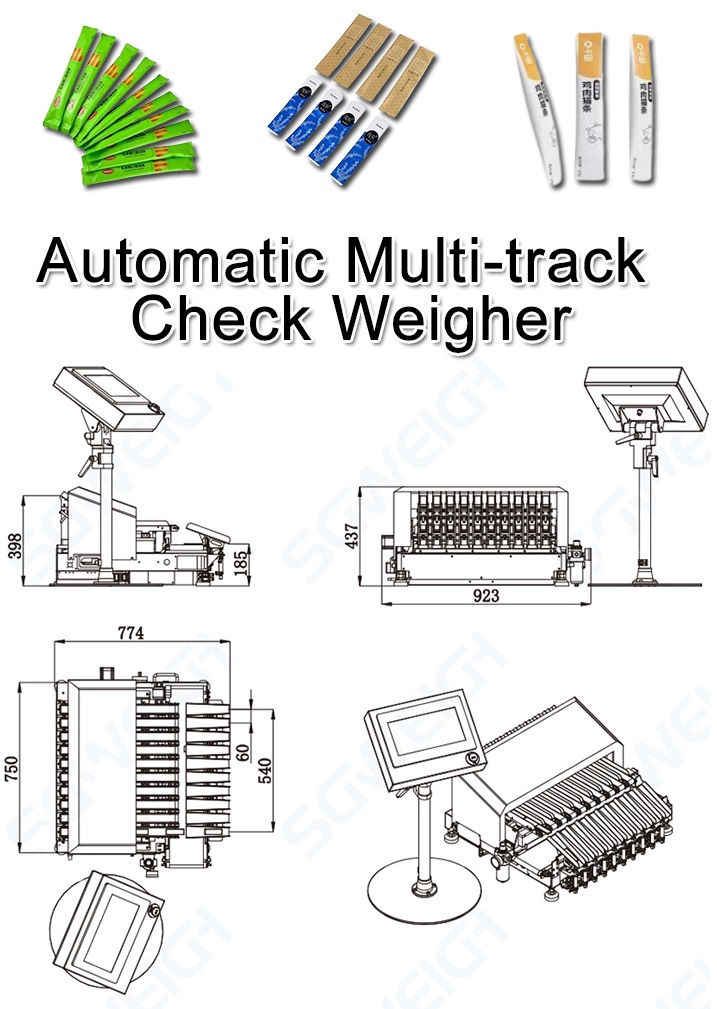

The Automatic Multi-Lane Slide Sorting Weigher includes a control cabinet and multiple belt checkweighing units in parallel, which can be connected to multiple single-row packaging machines.Long Soft Bag Granule Check Weighing Machine can weigh and sort multiple rows of packaging bags or soft bags with high precision at the same time.The patented plate rejection device can realize multi-row weighing and rejection.Welcome to consult for quotation information !

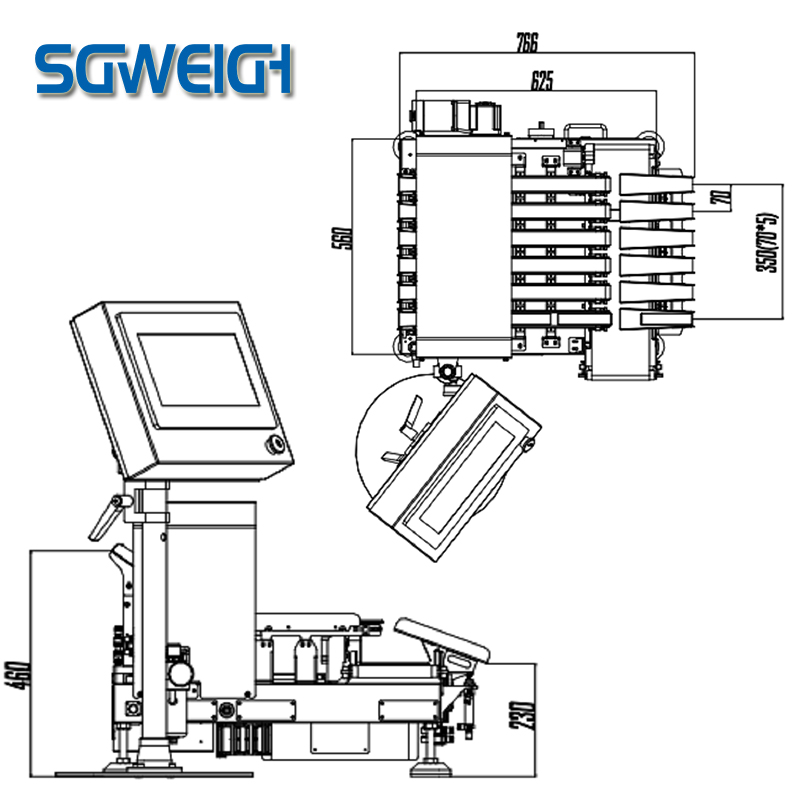

Technical Parameters

Weighing Range:1-30g

Minimum Scale:0.01g

Sorting Speed:Maximum 50 pieces/min (one channel)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

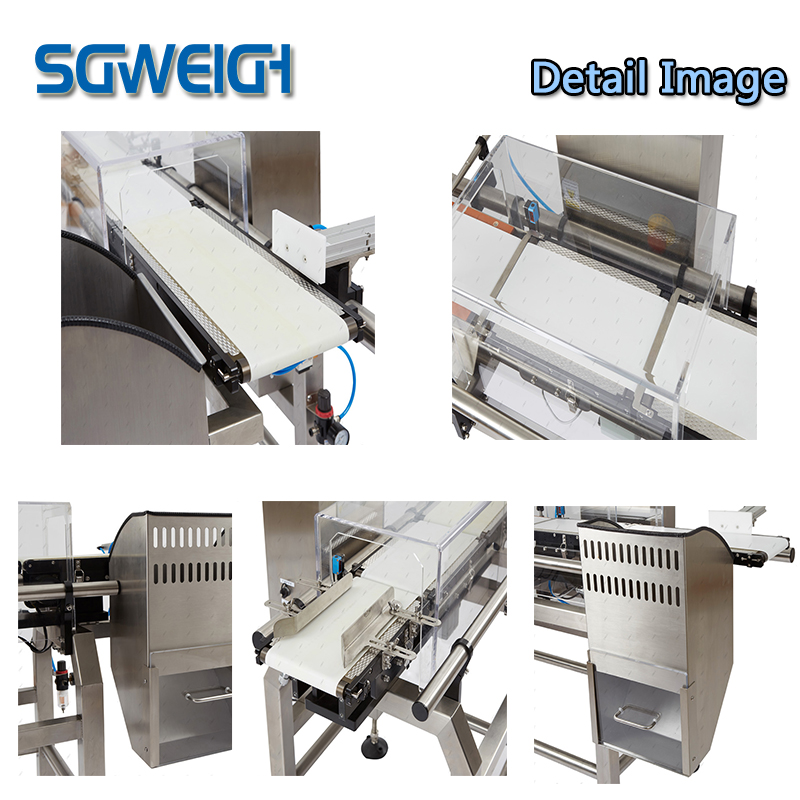

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About 1000W

Windshield:Thick acrylic (to avoid airflow interference)

Working Environment:Temperature: 0℃~40℃, Humidity: 30%~95%

Main Features

1. Suitable for multi-row simultaneous automatic weight detection of small packaged products such as food, medicine, daily necessities, etc.

2. Greatly improve the detection speed per unit time

3. Effectively prevent empty packages, underweight, overweight and other defective products

4. Count the passed products and automatically remove unqualified products by the sorting device

5. Can be matched with multi-row packaging machines, automatic filling machines, metal detectors, etc.

6. Customized according to on-site production line requirements, automatic barcode scanning and inkjet coding systems can be configured

7. The number of detection columns can be customized according to customer needs (such as double columns, four columns, six columns, ten columns, etc.)

8. Each channel can eliminate unqualified products separately.

9. The number of consecutive unqualified products in each channel can be modified.

10. Statistical data of each channel: real-time result display, trend chart display, histogram display.

Application

Our Customers

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

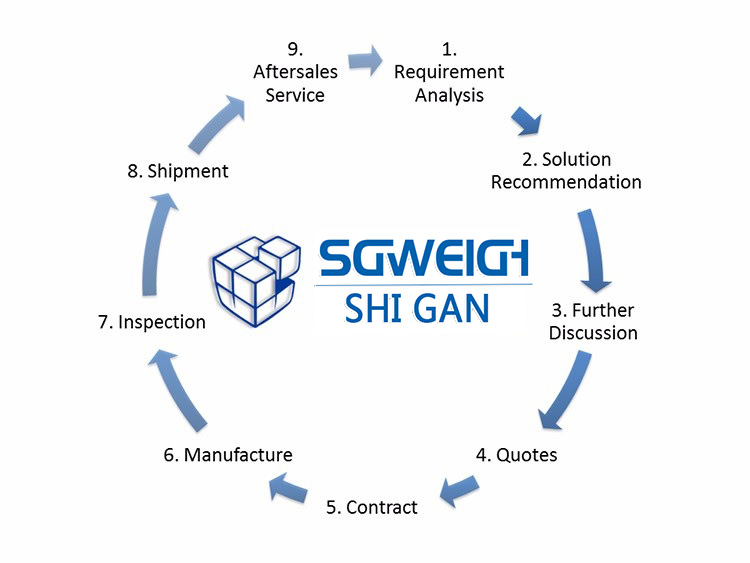

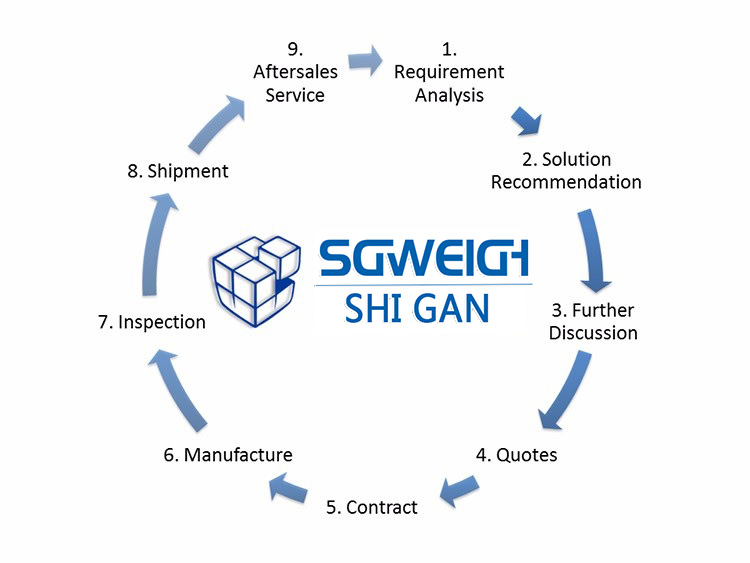

After Sale Service

1.Product quality commitment

(1).There are quality records and testing data for the manufacture and testing of products.

(2).For the inspection of product performance,we sincerely invite users to inspect the whole process and performance of the product in person.After the product is confirmed to be qualified,it will be packaged and shipped.

2.the product price commitment

Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment

Product delivery time: as far as possible according to user requirements,if there are special requirements,it needs to be completed in advance,and strive to meet user needs.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo